The use of bioplastics for construction products

A project financed by the Danish Agency for Science and Innovation.

Plastics materials are finding use in all aspects of industry and have great influence on our lives.

Conventional plastics are produced from raw materials based on fossil fuels. To avoid exhausting these materials, it is important to find renewable resources that can replace them in the production of plastics.

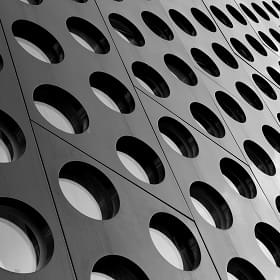

The project goal is to explore the possibility of replacing conventional plastic types with bioplastics. Both biodegradable plastics and bioplastics are considered.

The aim is to expand awareness and promote the use of bioplastics in the production of construction products, as well as to evaluate the possibility of recycling the materials in this production to avoid any environmental impacts and waste. This would be achieved through a combination of theoretical considerations and practical experiments at the participating companies.

Bioplastics generally have poorer thermal properties and this can be a barrier to their usage. Part of the project will be to test the effect of repeated thermal exposure on material properties. The results should be compared with conventional plastics where possible.

The plan is to make test samples, where the material is injection moulded and reground 10 times, and at every cycle samples are taken for testing in order to monitor any change in properties. The mechanical properties of the samples are tested (specifically tensile testing and impact testing) as well as the thermal and chemical properties (via DSC, TGA, FTIR and MFI).

This is a collaborative product between the industry and scientific participants.

The results achieved so far were presented on a poster at the conference “Bioplastic from plant based biomass”. BioValue SPIR and Novozymes hosted the conference for large sized companies and academic groups.

As shown in the poster ”Effects of reprocessing on thermal and mechanical properties of biodegradable PLA and bio based PA 4.10” has the thermal stability of the bio degradable thermoplastic polyactid acid, PLA, been investigated.

In addition is the thermal stability of three bio based thermoplastics, PA 4.10, PA 6.10, and isosorbidbased polycarbonate PC, is investigated. The first results for PA 4.10 were presented in the poster.

The project further more works on evaluation of thermal stability for PA 6.10 and isosorbidbased PC through measurements of both thermic and mechanical properties after 10 injection-molding cycles.

DMN members can read publications about the project in Danish here >

For further information, please contact:

For further information, please contact:

- Dorte Walzl Bælum

- Network Director

- B.Sc. Chem. Eng., M.Sc. in Business

- M: 60 35 19 90

- E: dwb@dmn-net.com